It’s About Time – Australian-made Water Play Makes a Splash

Water play is one of the most popular elements in Australian play spaces. It is also one of the most frustrating to specify, source, deliver, and maintain. Long lead times, imported components, inconsistent systems, and complex plumbing requirements can turn what should be a highlight of a project into a bottleneck.

Share post

With decades of experience designing, engineering, and manufacturing play equipment in Australia, we have seen first-hand how offshore supply chains can slow projects and complicate delivery. As the country’s largest manufacturer, we believe it is our role to provide Australian-made alternatives that reduce risk, improve lead times, and give designers and asset owners clearer options from the start.

When we looked at water play specifically, it was clear the market had accepted unnecessary complexity for too long. Long lead times, mismatched components, and systems that were difficult to adapt or maintain had become the norm. We saw an opportunity to rethink water play with a focus on standardisation, durability, and local manufacturing.

Reece Conley, Head of Marketing, Moduplay Group

What We Set Out To Change

When we started work on this range, the goal was not simply to manufacture water play locally. It was to rethink how water play is specified, delivered, and supported over the life of a project.

Too often, water play systems introduce unnecessary complexity. Design decisions are made late, configurations are unclear, and technical constraints only surface once a project is already underway. We wanted to change that by creating a range that is designed around clarity, consistency, and speed, without sacrificing durability or play value.

Built With Depth, Released with Intent

Behind this range sits a full suite of technical information. Installation guidance, standard heights, sizing, configuration rules, and clear do’s and don’ts have all been developed as part of the design process.

Rather than releasing everything at once, we are introducing the range in stages. This first release is about setting direction and starting conversations. Detailed technical resources, cheat sheets, and configuration guides will follow, giving project teams the information they need at the right time in the design process.

This approach allows us to support projects properly, without overwhelming early planning stages or encouraging unnecessary customisation.

A First Look, Not The Full Story

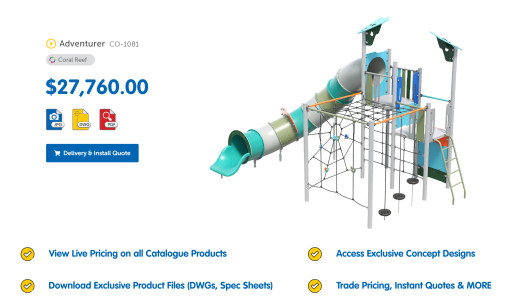

Below is a small selection of components and configurations from the new Australian-made water play range. These examples are intended to show the design intent, material quality, and flexibility of the system, not to define its full capability.

Each element has been developed to work within a broader, standardised framework that supports efficient design, quoting, and delivery.

Designed To Support Real Projects

Water play is popular, but it can also be one of the easiest elements to derail a program when details are unclear or supply chains fall apart. By manufacturing locally and designing around standardised configurations, we are able to offer clearer pathways from concept through to installation.

This means fewer surprises, more predictable outcomes, and better alignment between designers, contractors, and asset owners.

Want To Know More?

IIf you are working on a project and would like more detail, our team can provide additional information on configurations, installation requirements, and available options.

Moduplay – Bringing Play to the World since 1989

Today, Moduplay Group is a leading manufacturer of outdoor recreation products, serving a diverse range of clients across Australia and the world. We specialise in fulfilling contracts for Councils and Government bodies, Childcare and Education sectors, Landscape Architects and Designers, Builders and Developers, as well as several other sectors, with a strong commitment to delivering the best possible outcomes for our clients.

With employees from many different backgrounds with a broad variety of skill sets – Play designers, CAD experts, engineers, welders, CNC operators, carpenters, project managers, installers, support staff and a director team with long association with the industry, all work together to give back to our customers amazing products and outstanding play and recreation spaces.

Sustainability

We strive to deliver the smallest possible carbon footprint by manufacturing in Australia and intelligently choosing low-polluting materials and processes.

Australian Prosperity

Supporting Australian jobs supports and strengthens

local communities.

Continual Investment

We invest heavily in IT and automated machinery, as well as the skills of our people. This focus delivers leading-edge playground designs and streamlined processes that ultimately reduce your cost.

Reliability

We’ve been working with Australian schools, councils and LGAs for over 30 years.

Fully local end-to-end service

All design, engineering, manufacturing, installation,

and service are provided in Australia and we’ve been doing it that way since we first opened our doors back in 1989.

Quick turnaround

Local means more responsive service, better lead times and faster delivery.